What does a pre-made pouch pick-fill-seal machine do?

Our pre-made pouch pick-fill-seal machine receives pre-made pouches from a horizontal magazine feeder. A servo driven intermittent rotary pick 'n' place selects and rotates the pre-made pouches to a registered position where the pouch grippers grasp the tops of the pouches with precision. The grippers deliver the pouches to the opening station where pneumatic suction cups engage the front and back panels of the pouch to pull it open as mechanical arms reach into the pouch to unzip the zipped pouches. The pouches move to the reject station and are tested for product acceptance, then ejected from the machine if not properly opened. The open pouches are loaded by hand or automatically with an added filling feature. The pouches then come to the sealing station where the tops of the pouches are sealed with a set of heated jaws, then the finished pouches are discharged from the machine.

Pick-Fill-Seal

Pre-Made Pouch Applications

In the last 5-10 years pre-made pouches have been slowly dominating the shelves with their versatility.

They can hold anything a carton can. And More.

Liquids, candies, cannabis, coffee, stick packs, cookies, frozen dough, even macaroni and cheese or hardware kits can be packaged in a pre-made pouch. This can be done by hand, with an auger, net weigh scale, combination weigher, volumetric cup filler, piston filler, or custom robotic automation. We can assess your application to find the best way to carefully and efficiently transfer your product into the pre-made pouches.

Feature Options

The base equipment across all of our lines utilize the same framework and theory, allowing for us to focus on the part that matters - the best way to handle your products. Our equipment development starts with you. We form an ongoing relationship with our customers and their product lines, finding the preferred practices to produce the best looking packages while maintaining the integrity and consistency of the product inside the packaging.

Almost all of our feature options are standardized equipment. Combining these standard features in the right combination, we can create a machine custom for your specific product, package, and speed. We can also provide machines with the intention to grow. As a result of our dedication to growth, you can start off with a hand-load machine now and add any of the options later to increase automation.

Stop Wasting Product

Standard programming for No Product/No Pouch and No Pouch/Product Bypass. This ensures that product and packages aren't wasted.

Work on Equipment Safely

Separate high and low voltage electrical enclosures allows you to perform maintenance and repairs under power without being exposed to dangerous high voltages.

Clean and Maintain with Ease

Open frame design allows debris to fall straight to the floor without obstruction and lexan guard doors are easily removed for optimal access during maintenance and cleaning.

Building Block Design

Fully Convertible for Your Needs Today, Tomorrow,

and the Future

Our knack for simplicity coupled with our expertise in filling and handling has led us to design our equipment so that all features can easily bolt-on. To adjust to your needs, you may add auxiliary equipment from the Yeaman Arsenal, or your own at any point in your equipment's lifetime. You can create different configurations by adding and removing product and package handling features. In essence, you can convert your machine to run loose fill, stick packs, kits and more all on a single machine!

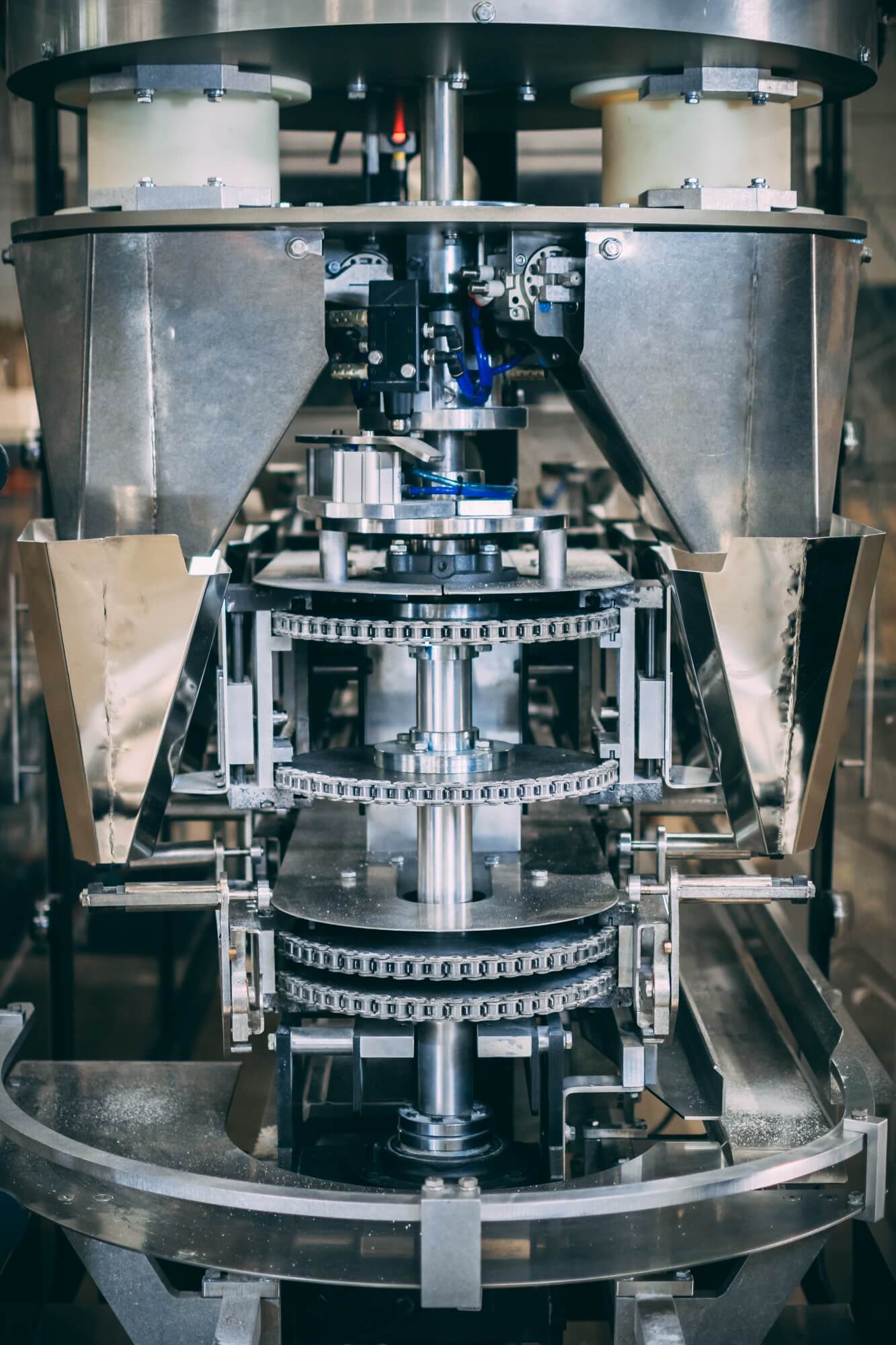

Quick Changeovers

The changeover times on our carousal style pouch fill and seal machines are quick for one individual to perform, run to run. While many of our competitors offer adjustable pouch carriers, we have found that our tool-less quick-change grippers simplify the entire changeover procedure. This theory of pouch handling is to construct a carrier gripper in a fashion that is rugged enough to withstand tough production environments while remaining consistent in its carrying and positioning abilities. By doing so, this enables the machine to perform the necessary operations of holding, filling and sealing the pouch to produce the cleanest and best possible seal for a presentable package.

Switching out individual pouch carrier grippers for your next pouch size accounts for two of the three pouch dimensions--the length and width of opening. Next, the carriage height is adjusted with a handwheel to a dimension marked to match the height of the pouch. The following mechanical adjustment is on the magazine. Using a handwheel, simply adjust to the marked dimension that accounts for the new width of the flat pouch.

The final procedure required for change-over is choosing the new recipe on the HMI touch screen. This will adjust programming settings such as sealing time and temperature for your next pouch run. Some minor individual adjustments may be required to accept film run variations. With these simple procedures, changeover to run time is reduced to the minimum.

3-Sided Seal

Child Proof

Doypack

Fin Seal

Handled

K Style Bottom

Plow Bottom

Shaped

Slider

Zipper

| Model A | Model B | Model C | Model D | Model E | ||

|---|---|---|---|---|---|---|

| Standard Pouch Sizes Width x Height x Gusset |

MIN 3" x 4" x 0" MAX 8" x 12" x 4" |

MIN 5" x 5" x 0" MAX 12.5" x 17" x 6.5" |

MIN 8" x 8" x 0" MAX 17.5" x 22" x 8.5" |

|||

| Max Pouch Weights |

6 lb | 12 lb | 24 lb | |||

| Speed Actual Rates Determined |

Variable to 40/ppm | Variable to 70/ppm | Variable to 30/ppm | Variable to 50/ppm | Variable to 20/ppm | |

| Motion |

|

|

|

|||

| Machine Sizes Length x Width |

110" x 108.5" | 150" x 108.5" | 165" x 127.25" | 225" x 127.5" | 220" x 138.5" | |

| Additonal Length Increments May Be Required Based |

40" | 60" | 80" | |||

| Working Elevation Where Product Enters the Pouch |

36" | 40" | 50" | |||

| Standard Construction |

|

|||||

| Optional Construction |

|

|||||

| Controls |

|

|||||

| Electrical Power Requirements | Wired To Your Plant's Specifications | |||||

| Pneumatic Power Requirements | Approx. 16 CFM 80 psi | |||||